Paper Chemical Equipment

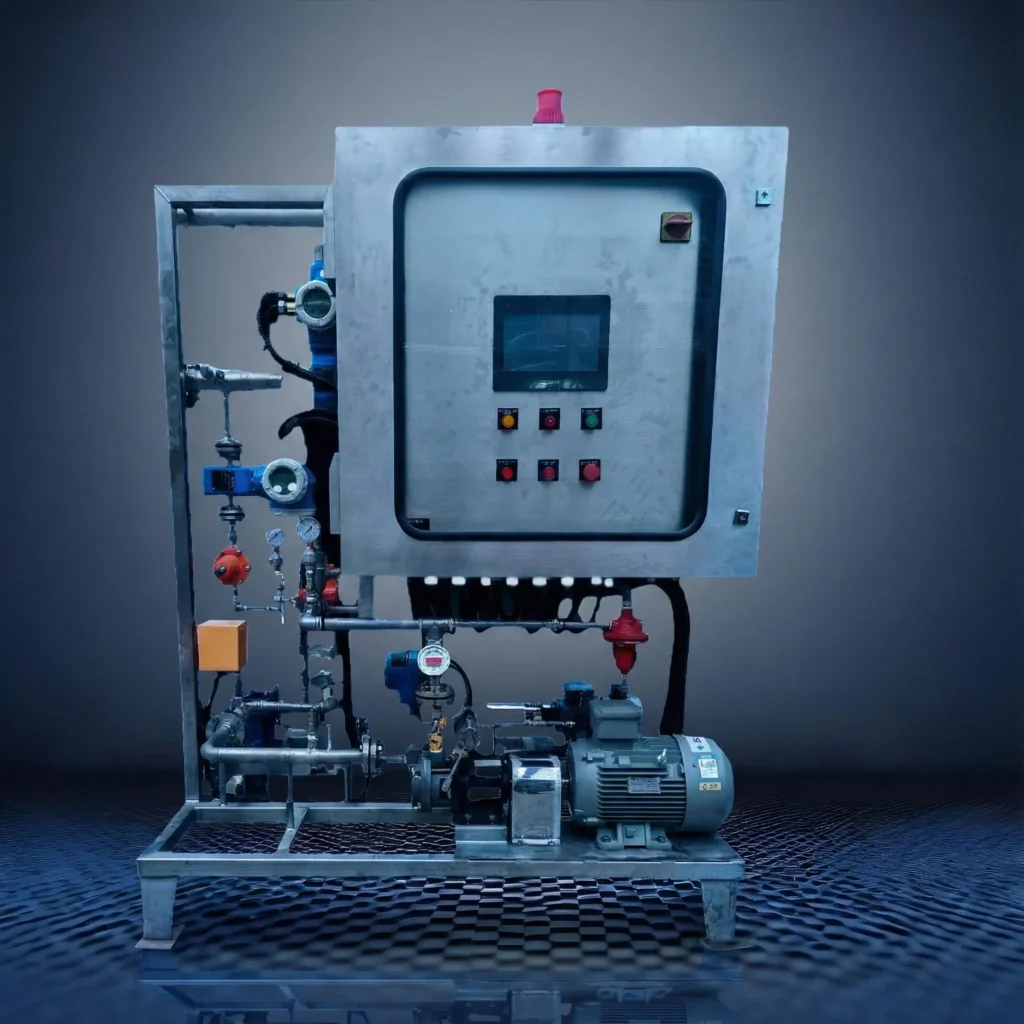

ASA Emulsifiers

Klasco offers a state-of-the-art ASA Emulsifier designed to emulsify ASA in cooked starch and feed the emulsion directly to the paper machine.

Key Features:

High Capacity

Emulsifies ASA at rates up to 150+ kg/hr and supports starch flows up to 400+ LPM.

PLC Controlled

Ensures precise ratio control of starch to ASA for optimal performance and includes a flow-following mode for multi-ply splitter applications.

User-Friendly Interface

Equipped with a graphical operator interface terminal for easy monitoring of process parameters.

Compact and Durable Design

Features a compact design with a stainless steel frame and piping. It comes pre-piped, pre-wired, and ready to operate.

Versatile Options

Standard options include an IP55 electrical enclosure, with available upgrades to IP65 stainless steel enclosures and IEC listed panels, compatible with various voltages and 50 Hz power.

Experienced Support

Backed by extensive on-site startup services and years of experience in paper chemical equipment startup experience.

A full range of accessories is available including starch pumps, starch filters, emulsion filters and splitter systems for multi-ply applications.

Explore our standard designs for cooked starch, pre-cooked starch, and polymer to find the perfect solution for your needs.

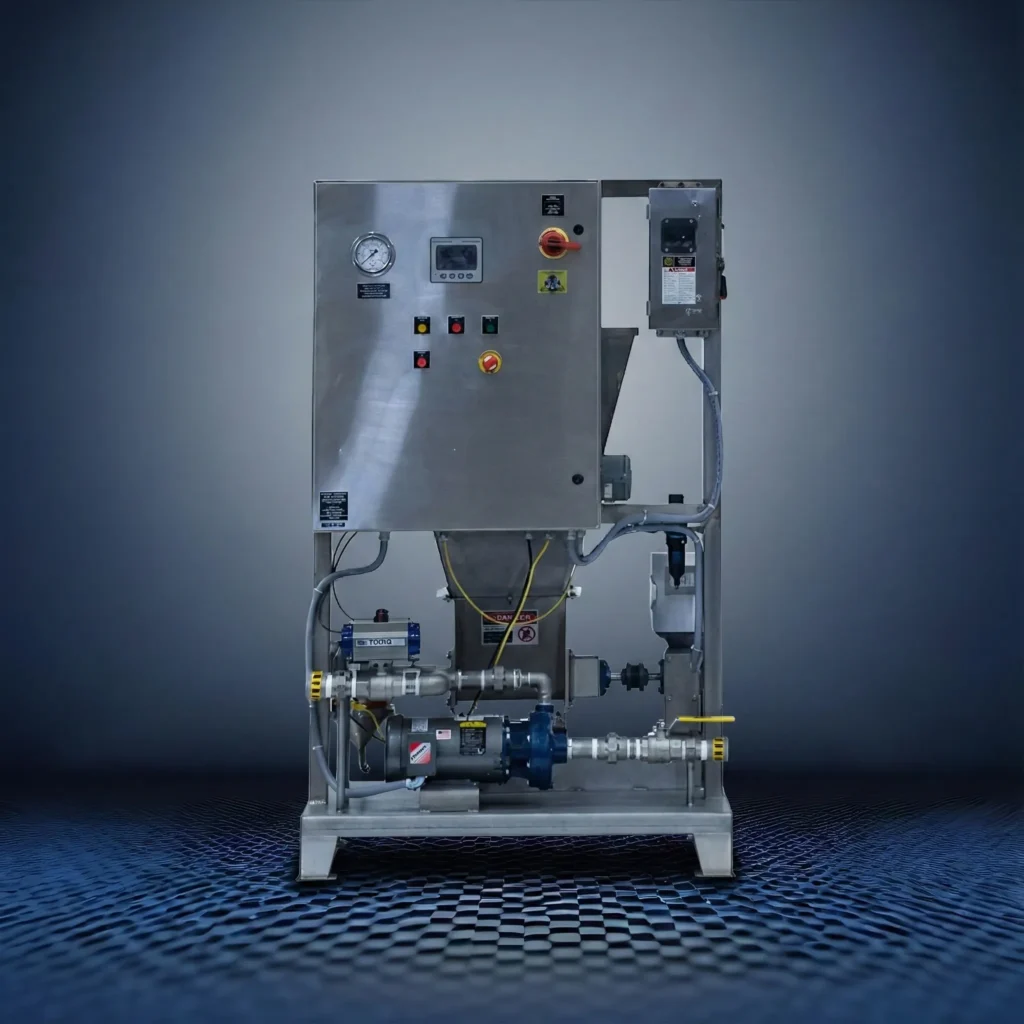

Liquid Polymer Systems

Klasco offers a reliable and efficient Liquid Polymer Makedown System designed to handle liquid emulsion polymers and deliver consistent results.

Key Features:

High Capacity

Supports makedown flow rates up to 400+ LPM and neat flow rates up to 3,000+ cc/min.

Precise Control

Equipped with PLC/HMI control to ensure accurate concentration and process monitoring.

Compact and Durable Design

Features a space-efficient design with a stainless steel frame and piping, pre-piped, pre-wired, and ready to operate.

Versatile Options

Standard options include an IP55 electrical enclosure with upgrades available to IP65 stainless steel enclosures and IEC listed panels, compatible with various voltages and 50 Hz power.

Comprehensive Accessories

Includes transfer pumps, run/storage tanks, and filters.

Experienced Support

Backed by extensive on-site startup services and years of experience in paper chemical equipment startup experience.

Our polymer systems offer proven technology in a compact footprint, designed to break down emulsion polymers in water and feed them to a mix tank. These systems fit a wide range of applications with standard designs that feature precise control and user-friendly interfaces.

A full range of accessories is available including tanks, transfer pumps, filters and hoses.

Explore the capabilities of our Liquid Polymer Makedown System to find the perfect solution for your needs.

Dry Polymer Systems

Klasco presents the Pol-e-Duc Dry Polymer Makedown Systems, engineered for superior performance and reliability. Our systems ensure a uniform, consistent product free of ‘fish eyes’ and agglomerates, maintaining concentrations up to 6%.

Key Features:

High Capacity

Capable of handling up to 4500+ kg/day.

Uniform and Consistent Product

Ensures polymers are fully wetted and free of lumps and agglomerates.

Safety and Cleanliness

Operates by vacuum to draw in any powder leaks, eliminating dust and maintaining a clean workspace.

Process Stability

Automated controls provide tight control over operating parameters, reducing process variability and ensuring consistency from batch to batch.

Automated System

Utilizes PLC control, along with level transmitters for precise operation.

Durable Construction

Built with a stainless steel frame and base plate, ensuring long-lasting durability.

Additional Features:

Precise Concentration Control

Closely controls polymer concentration with an operator interface terminal to monitor all process parameters.

Compact Design

Features a space-efficient design with a stainless steel frame and piping, pre-piped, pre-wired, and ready to operate.

Versatile Options

Standard options include an IP55 electrical enclosure, with upgrades available to IP65 stainless steel enclosures and IEC listed panels, compatible with various voltages and 50 Hz power.

Experienced Support

Backed by extensive on-site startup services and years of experience in paper chemical equipment startup experience.

A full range of accessories is available including tanks, transfer pumps, filters and hoses.

Explore the capabilities of our Dry Polymer Makedown Systems to find the perfect solution for your needs.

Bentonite Makedown Systems

Klasco offers advanced Bentonite Makedown Systems designed to create high-quality bentonite slurries with concentrations up to 7%. Our systems ensure efficient and reliable operation, making them an ideal choice for a variety of applications.

Key Features:

High Capacity

Supports bentonite flow rates up to 830+ kg/hr and slurry flow rates up to 200+ LPM.

Precise Control

Equipped with PLC/HMI control for accurate operation and monitoring.

Compact Design

Features a space-efficient design with a stainless steel frame and piping, pre-piped, pre-wired, and ready to operate.

Versatile Options

Standard options include an IP55 electrical enclosure, with upgrades available to IP65 stainless steel enclosures and IEC listed panels, compatible with various voltages and 50 Hz power.

Experienced Support

Backed by extensive on-site startup services and years of experience in paper chemical equipment startup experience.

A full range of accessories is available including big bag hopper, slurry filters, external storage tank, transfer pump, and dosing pump skid.

Explore the capabilities of our Bentonite Makedown Systems to find the perfect solution for your needs.

Bentonite Makedown Systems

Klasco offers advanced Bentonite Makedown Systems designed to create high-quality bentonite slurries with concentrations up to 7%. Our systems ensure efficient and reliable operation, making them an ideal choice for a variety of applications.

Key Features:

High Capacity

Supports bentonite flow rates up to 830+ kg/hr and slurry flow rates up to 200+ LPM.

Precise Control

Equipped with PLC/HMI control for accurate operation and monitoring.

Compact Design

Features a space-efficient design with a stainless steel frame and piping, pre-piped, pre-wired, and ready to operate.

Versatile Options

Standard options include an IP55 electrical enclosure, with upgrades available to IP65 stainless steel enclosures and IEC listed panels, compatible with various voltages and 50 Hz power.

Experienced Support

Backed by extensive on-site startup services and years of experience in paper chemical equipment startup experience.

A full range of accessories is available including big bag hopper, slurry filters, external storage tank, transfer pump, and dosing pump skid.

Explore the capabilities of our Bentonite Makedown Systems to find the perfect solution for your needs.

Aluminium Sulphate Makedown Preparation System

Klasco offers a state-of-the-art Aluminium Sulphate Makedown Preparation System designed for efficient and reliable preparation of Aluminium Sulphate solutions for various industrial applications. Our system ensures optimal performance and ease of operation, making it an ideal choice for water treatment plants, paper mills, and other industries that utilize Aluminium Sulphate slurries in their processes.

Key Features:

High Efficiency

Designed for the precise preparation of Aluminium Sulphate solutions, ensuring consistent and accurate dosing.

Robust Construction

Built with high-quality materials, including stainless steel frames and piping, to withstand harsh industrial environments.

Advanced Control

Equipped with PLC/HMI control systems for easy operation and real-time monitoring.

Compact Design

Space-efficient design that fits seamlessly into existing setups, with pre-piped and pre-wired components for quick installation.

Automated Operation

Fully automated system to ensure consistent preparation and dosing, reducing manual intervention and increasing reliability.

Safety and Compliance

Designed to meet stringent safety standards.

Easy Maintenance

Features that facilitate easy cleaning and maintenance, ensuring long-term reliability and efficiency.

Experienced Support

Backed by extensive on-site startup services and years of experience in paper chemical equipment startup experience.

A full range of accessories is available including external storage tank, transfer pump, and dosing pump skid.

Our Aluminium Sulphate Makedown Preparation System is engineered to deliver consistent performance and peace of mind, ensuring that your processes remain efficient and effective. Explore the capabilities of our system to find the perfect solution for your needs.

Sulfuric Acid Dilution & Dosing Skids

Klasco provides advanced Sulfuric Acid Dilution and Dosing Skids, engineered for precision, safety, and efficiency. Our systems are designed to meet the rigorous demands of industrial applications, ensuring accurate dilution and dosing of sulfuric acid.

Key Features:

Precision Dilution

Accurate and reliable dilution of sulfuric acid to the desired concentration.

Precise Dosing

Ensures exact metering of sulfuric acid for consistent and controlled application.

Robust Construction

Built with corrosion-resistant materials, including high-grade stainless steel and specialized plastics, to withstand harsh chemical environments.

Advanced Control Systems

Equipped with PLC/HMI controls for easy operation, monitoring, and integration with existing systems.

Compact Design

Space-efficient design that integrates seamlessly into existing setups.

Safety and Compliance

Designed to meet stringent safety standards, ensuring safe operation and handling of sulfuric acid.

Corrosion Resistance

Use of materials that provide high resistance to sulfuric acid, enhancing the longevity and reliability of the system.

Customizable Options

Available with various options to meet specific customer needs, including different enclosure types, flow rates, and control systems.

Easy Maintenance

Features that facilitate easy cleaning and maintenance, ensuring long-term reliability and efficiency.

Experienced Support

Backed by extensive on-site startup services and years of experience in paper chemical equipment startup experience.

Our Sulfuric Acid Dilution and Dosing Skids are designed to deliver reliable performance and safety, ensuring optimal operation in a variety of industrial applications. Trust Klasco for your sulfuric acid handling needs and benefit from our commitment to quality and innovation.